AIS X-Ray Micron Scan

The AIS X-Ray Micron Scan is 225x more powerful than a standard food inspection system.

Our newest and most advanced scanner offers a resolution 225 times more powerful than a standard x-ray food inspection system1.

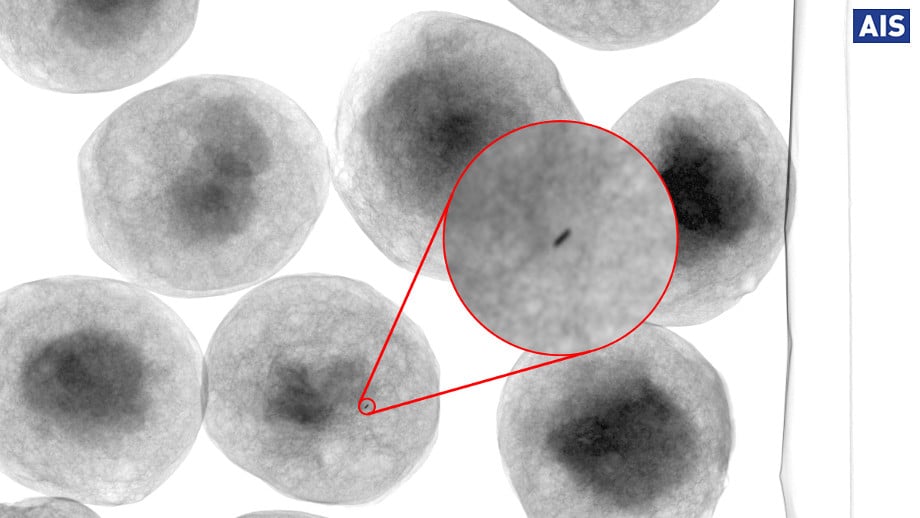

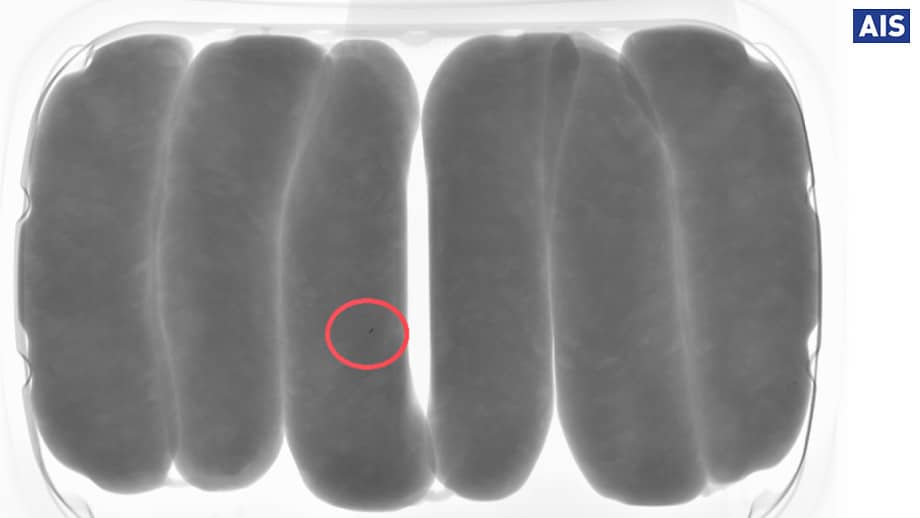

Extremely Powerful Detection

The extremely high resolution of this scanner is achieved using advanced linear sensors that can accurately detect minute contaminants. Its detection capabilities are increased by the sensor being less dependent on the orientation and location of a foreign body within the product.

The Micron Scan excels at the inspection of loose products such as flours or powders where the contaminants are likely to be extraordinarily small and difficult to detect.

This level of detection is not possible on today’s high speed production lines. The Micron Scan is designed to operate off-line and – to achieve optimum accuracy – be operated by our expert staff.

Detection Sensitivity

Accuracy

Quality assurance, assured

The AIS X-Ray Micron Scan can detect glass fragments down to 1.0mm and stainless steel wire to 0.1mm as well as stone, calcified bone and certain rubbers and plastics.

Comprehensive detection

Identify defects without damaging goods

Trusted by clients

90% of inspections are repeat business

ISO 9001 certified

Accredited for our Quality Management System

Certified since 1999

Europe’s first ISO-certified X-ray inspection service

- The following resolution can be achieved in a 15cm x 15cm product sample:

Typical food inspection system – 140,000 data points

AIS X-Ray Ultra Scan – 600,000 data points

AIS X-Ray Micron Scan – 9,000,000 data points

Our x-ray inspection service allows you to outsource or verify your quality assurance procedure for a challenging contaminant issue.

Potentially affected product batches can be delivered to AIS, inspected, and any safe product returned to the shelves in a very short turn-around.

AIS offer an alternative high resolution x-ray scanner, the Ultra Scan, to deploy at near-line and off-line locations at your own premises.

AIS X-Ray Ultra Scan

The Ultra Scan offers a resolution 15 times more powerful than a standard system and can be installed at your premises on a short-term basis.

Why choose us?

AIS X-Ray Micron Scan FAQs

What can the Micron Scan detect?

Our highest resolution x-ray scanner can detect extraordinarily small contaminants:

- A sieve wire of just 0.2mm in a single item

- A piece of metal just 1.0mm sphere in a multi-pack or case

- Glass fragments down to 1.0mm

- As well as stone, calcified bone and certain rubbers and plastics

Can the new AIS X-Ray scanners operate on-line or near- line?

Ultra-high resolution sensors cannot match the high speeds used on modern production lines.

The AIS X-Ray Micron Scan is designed to operate off-line and be operated by AIS’ expert staff to achieve its optimum accuracy.

The AIS X-Ray Ultra Scan can be deployed at near-line and off-line locations.

How are the x-ray inspection machines set up?

All systems consist of a conveyor cabinet and x-ray generator plus high powered PC and software for x-ray detection and image processing.

To take full advantage of the higher resolution, the image processing hardware and software must be able to handle the data rate that the detectors produce. The hardware and software within the Micron Scan and Ultra Scan are optimised to handle these high data rates.

Can I hire x-ray inspection equipment?

Yes, some of our customisable x-ray inspection systems and metal detectors are available to rent at your premises. These can be hired, subject to availability, on flexible contract periods – usually for an immediate or short term requirement.

Find out more about X-Ray Inspection Equipment Hire.

What is our Free Sample Inspection?

Our Free Sample Inspection service offers a no obligation evaluation of what is achievable for your product and problem. Simply complete the form here and send a sample of your product for inspection at AIS’ premises.

This initial evaluation is reasonably immediate, confidential and free and we will always provide an honest appraisal of what is possible. All enquiries are treated as 100% confidential.

You can also call us – we can often evaluate the issue on the phone.

Request free sample inspection

Free, immediate and confidential evaluation

Email Us

sales@aisx-ray.com

Call Us

+44 (0)1933 674030

Opening Hours

8am to 5pm – Monday to Friday (GMT)